My path to 3D printing

How I got into 3D printing and why I use which printer and software, I'll show you here 💡

Since I now own my Creality Ender 3s1*, I've been hard at work in the 3D printing game. After I painstakingly built and rebuilt my 3D printer, it was immediately given a few improvements (these will follow later here as an article). But back to the beginning...

The beginnings

Around about 2016-2017, I started flirting with the idea of a 3D printer. As my son was born at the same time and we moved into the house, money was naturally a bit tight. For this reason, I bought a cheap wooden FDM printer on Ebay and then familiarized myself with the material. So far so good.

But what I forgot (didn't think about) is the fact that the printer is made of wood. Humidity (especially in my office under the roof) can be high. We all remember from physics lessons that wood attracts water and works and swells accordingly.

Spoiler: You could never print anything clever with a printer.

So the printer had to be converted to aluminum. But as you know, I should have printed parts before the conversion. Stupid. I couldn't assemble it either because I just didn't feel like spending any more evenings in my man-cave. So I abandoned the project for the time being.

The return

Through a good friend Florian (https://wartner.io/), I came into contact with 3D printing again. This was partly due to the fact that I wanted to make my home a lot smarter. No sooner said than done. I bought the recommended Creality Ender 3s1* and set it up.

Prints pretty well at first and already miles better than the wood planer. But there's still room for improvement...

Professional firmware is the key

Admittedly, the software from Creality is ok. If you don't want to overdo it. From the "old" days, I still knew OctoPrint, which a) no longer looks up-to-date and) is somewhat outdated in terms of functionality.

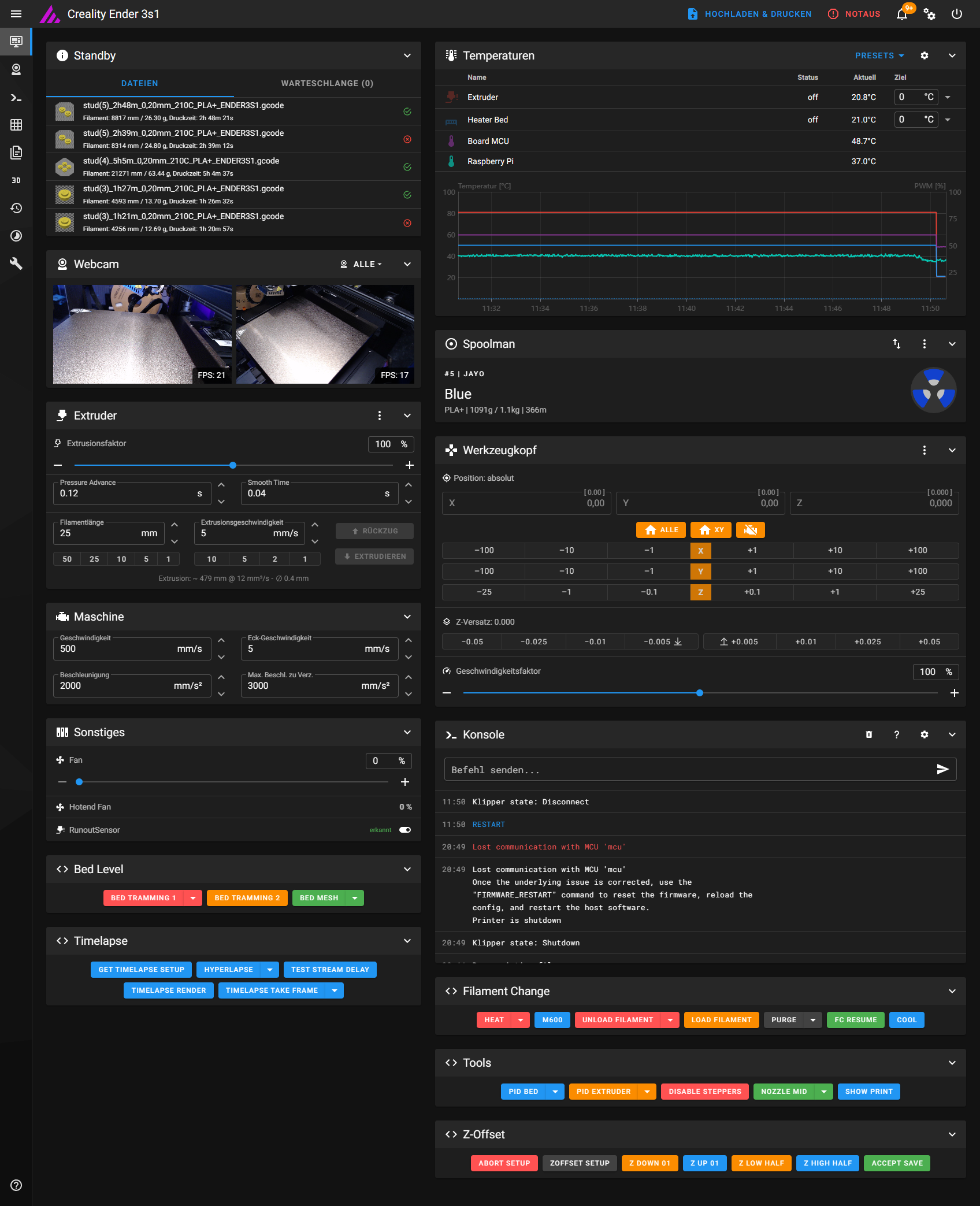

Florian then recommended Klipper to me. Just wow!

Klipper runs on a RaspberryPi, just like Octoprint, and offers a web interface with which you can do everything (and from anywhere, if it is configured):

But here's the clue: Klipper offloads the processing to the Pi and away from the MCU. What does that mean? Well, the printer itself no longer processes everything internally on the board, but the Pi now does this and sends all the commands to the specially baked firmware for the printer. What are the advantages? Faster and cleaner prints.

But that's just one of the nice things Klipper has to offer. Just take a look at Klipper:

I will also compile the installation process and configuration of Klipper as an article here later. Just sign up for the newsletter and stay up to date!

Digression: How sustainable is filament?

My girlfriend is very skeptical about it all. Who can blame her, in times when the idea of sustainability continues to grow and you want to leave your own child a "green" world, the "plastic is bad" idea is of course always more than latent when it comes to this topic. In other situations in life, you want to get rid of plastic completely and replace it with glass or other materials and now the guy with a 3D printer comes along.

It has a taste...

PLA (polylactide acid), for example, is one of the plastics that is most likely to be used in 3D printing. This is because it is easy to print, has good properties in terms of print stability and is also quite robust in subsequent printing.

The production of PLA, as confirmed by the Federal Environment Agency, is sustainable as it is obtained from corn starch. Point for PLA ✅

But many manufacturers also claim that PLA, for example, is readily biodegradable. Yes, that may be true if you want to market it as an argument, but it's not quite that simple. As I am not a chemist, I am happy to quote a source here:

Polylactic acid (PLA) is a biodegradable and compostable bioplastic. The DIN 13432-certified PLA decomposes to at least 90 percent within 90 days in an industrial composting plant. Decomposition outdoors usually takes longer due to various factors

Source: https://www.biologischverpacken.de/blog/materialien/pla-biokunststoff

And this is precisely where the problem lies. "In an industrial composting plant". Many of the surrounding "normal" waste disposal companies are unlikely to have one. Unfortunately, composting at home is not an option. This is likely to take a very, very long time.

I also found a nice YouTube video on this subject from HobbyHoarder, which explains the whole issue:

Now comes the dilemma

If you're inexperienced in 3D printing, as I am, then you quickly notice a lot of things that can be improved. Of course, you always have to do a test print every time so that you can see whether things have turned out the way you want them to.

There is also always waste, e.g. from prime lines, the brims or simply printing errors, which can happen again and again.

Since I got the printer (that was in August), I have already "burned" almost 2 kg of filament. Well, but what can you do if you're still setting up the printer? And you don't want to wait until the printer is perfectly adjusted (because btw, it never is, you always find something and the field of 3D printing is a miserable rabitthole anyway).

And that's where we come to the most important point I've found out for myself. Misprints are not bad, they happen. But you should be conscientious about them. You should check everything before every print.

Minor printing errors shouldn't lead to the whole object being thrown away, you might still be able to use it?

The key is: print consciously (even if I still don't always succeed).

Dann klappt's auch mit der Freundin

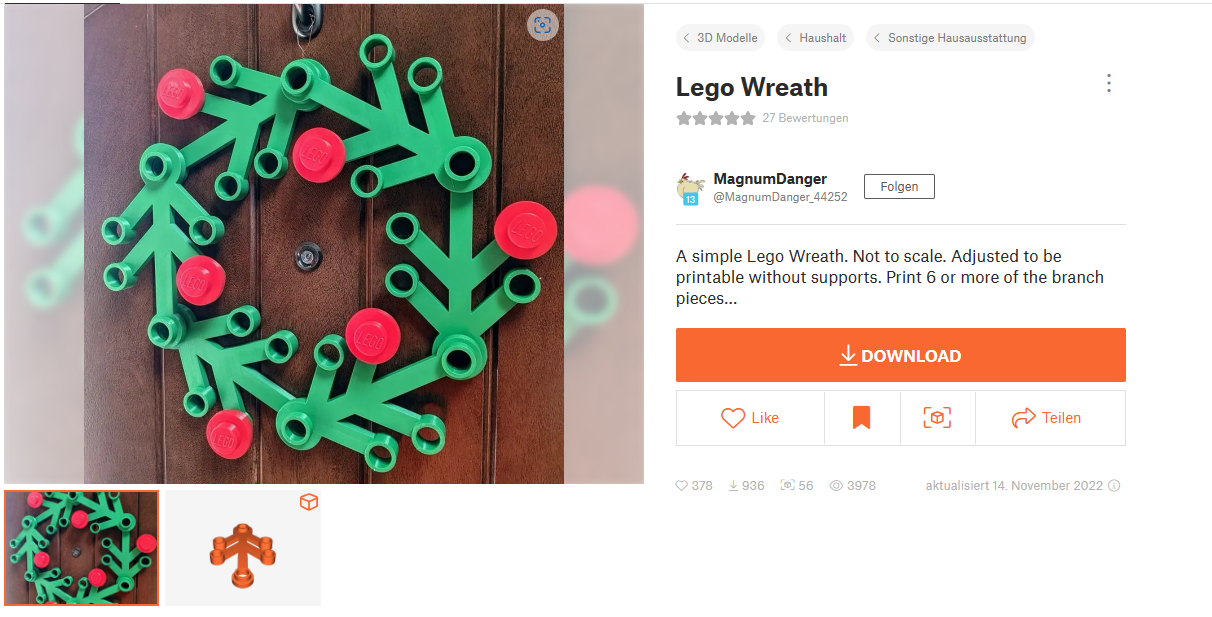

Now my girlfriend has exactly the same concerns (if not even greater) than I do on the subject. But since she's a huge Lego fan, I simply gave her my favorite model site: https://www.printables.com/

And there she let off steam and found a nice gimmick for Christmas: A Lego Christmas wreath.

And as you can see, the wreath is quite impressive. Even if it took a lot of blood money (in the sense of many test prints for the settings). It also turned out big 😛